AliExpress

Engine Cylinder Compressions Tester Kit 0-300PSI With M10 M12 M14 M18

Engine Cylinder Compressions Tester Kit 0-300PSI With M10 M12 M14 M18

Couldn't load pickup availability

Features:

--This automotive compression tester works with most car models with gasoline engines. It comes with adapters and pipes in different size to fit different models. Widely used for checking compression on engine cylinder quickly and accurately.

--Copper nickel-plated drain valve, anti-oxidation, corrosion-resistant.

--Air gauge with quick coupling & pressure release button, manometer with two test pressure: 0-300psi, 0-20bar.

--Included 4 adapters: M10*1.0mm / M12*1.25mm / M14*1.25mm / M18*1.5mm.

--M10 adapter for motorcycles, M12 M14 M18 adapter for motor vehicles.

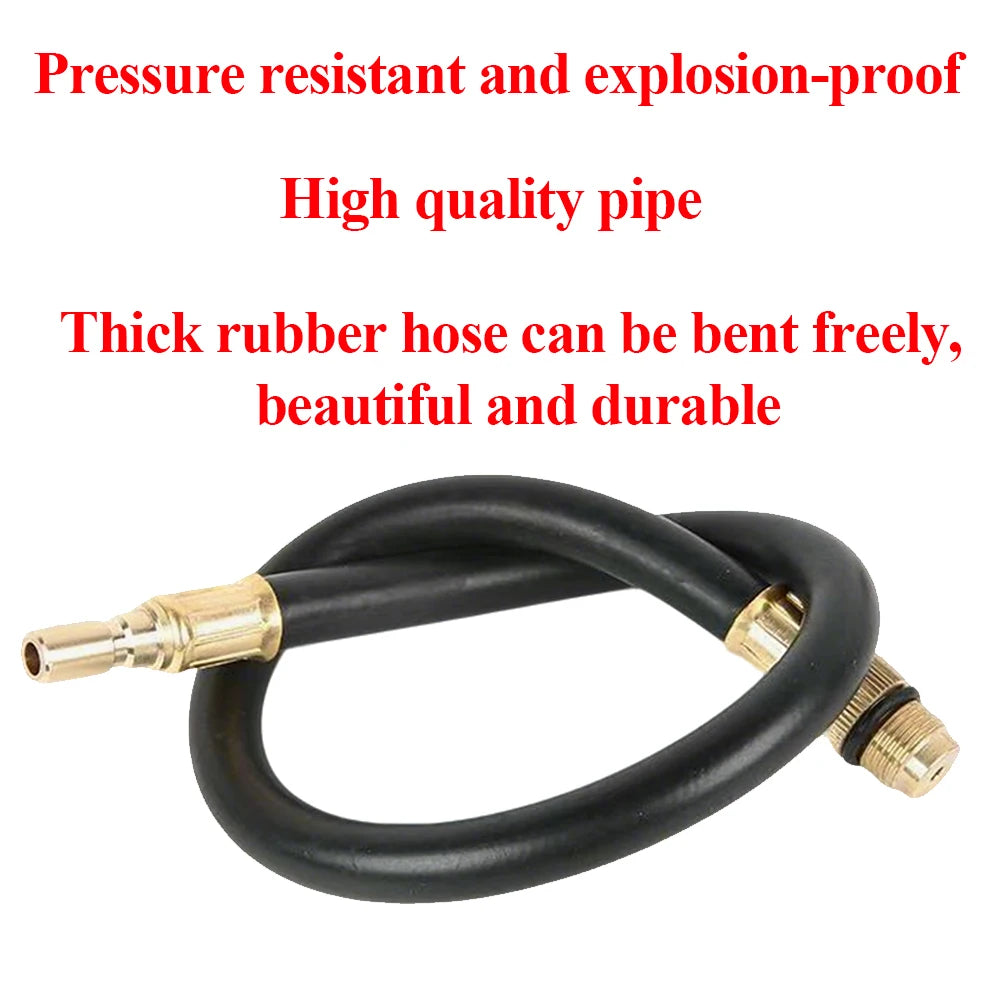

--Included 2 pipes: crank shaft type & transverse axis type, both with rubber cone cap and can test the compression on almost any engine.

--Easy-to-read instrument panel with dual units (0-300 psi, 0-21 kg/cm²). Acrylic glass gauge cover with anti-scratch coating and rubber protective cover for outstanding shock-absorption performance.

--Multi-size adapters (straight, curved, & male fittings) for compatibility with a wide range of vehicles. All components are protected in a ABS carry case for easy organization and transport.

--You can get accurate readings on the valve, piston ring, cylinder bore or head gasket.

Specification:

Specifications:

Case Color: Red

Material: Copper

Dual Gauge Readings: 0-300psi, 0-20bar (1bar=100kPa)

Test Unit/Mode: bar, psi

Special function: Get Accurate Readings

Adapters Thread Size: M10 x 1.0mm, M12 x 1.25mm, M14 x 1.25mm, M18 x 1.5mm

Package Content:

1 x Gasoline Compression Tester

1 x M18 x 1.5mm Adapter

1 x M14 x 1.25mm Adapter

1 x M12 x 1.25mm Adapter

1 x M10 x 1.0mm Adapter

1 x Angled Pressure Pipe

1 x Straight Line Pressure Pipe

1 x Hose

1 x Storage Case

Product instructions:

1. Start the engine and let it run to normal operating temperature (cooling water temperature 70-90 ° C)

2. Turn off the engine, clean the debris around the engine spark plug, and remove all spark plugs.

3. Set the throttle and choke to the fully open position.

4. Tighten the conical rubber joint of the cylinder pressure gauge into the spark plug hole of the tested cylinder (or screw the threaded pipe joint onto the spark plug hole).

5. Use the starter to drive the crankshaft to rotate for 3-5 seconds (no less than four compression strokes), read the reading after the pointer stabilizes, and then press the one-way button to return the pointer to zero.

6. Repeat step 5, it should be noted that each cylinder should be measured no less than twice, and the average of the measurement results should be taken.

7. Use the above method to sequentially test each cylinder.

In the diagnosis of automobile engine faults, by observing the changes in cylinder pressure readings, some mechanical faults inside the cylinder can be quickly diagnosed.

Method 1

Phenomenon: At the moment when the starter motor just rotates, the pressure gauge pointer rises very little. As time goes on, the pointer slowly rises, but the amplitude is not large. Eventually, the pointer does not move and the pressure gauge reading is still very low.

Reason for malfunction: The cylinder is not sealed properly, which may be caused by burnt valves or valve seat rings, insufficient valve clearance, or valve blockage by impurities.

Method 2

Phenomenon: At the moment when the starter motor just rotates, the pressure gauge pointer rises very little. As time goes on, the cylinder pressure gradually increases, but the final reading is lower than the standard value of the cylinder pressure.

Reason for malfunction: The piston and cylinder wall are not sealed, which may be due to severe wear and tear of the piston ring, breakage due to adhesive bonding, alignment, or wear and tear of the cylinder wall.

Method 3

Phenomenon: The pressure of adjacent cylinders is equal and both are low.

Fault cause: Two adjacent cylinders are connected, which may be caused by the adjacent cylinder pads being burned through, or the uneven upper and lower surfaces of the cylinder head and cylinder block.

Method 4

Phenomenon: The pressure of each cylinder is generally low.

Fault cause: Excessive wear or displacement of the half circle key of the camshaft timing gear.

Share